Learn about wood types and uses

Have you ever tried running a screw into MDF without drilling a hole? If you have you'll discover something about wood types and uses. MDF is not wood but wood particles and hard resins bonding it together to make a very hard smooth surface. When you attempt to run a screw through MDF you are displacing the volume of the screw forcing it out causing cracks if there is not enough adjacent area around the screw.

Mississauga handyman carpentry always pre-drills holes in MDF because we know what types and uses concerning hardwoods and particleboard and MDF. These are all very hard materials that require this. Just by drilling a hole a little smaller than the root diameter of the thread will allow easy insertion of the screw without cracking or damaging the wood.Pre-drilling might seem like a waste of time but it's less of a waste of time that to replace the wood because it has been damaged due to not knowing how to handle wood types and uses.

For example, when you are putting deck boards on a wood deck and you are screwing the end of the board to the joists you'll probably have noticed that most times the wood splits if it's too close to the edge. When installing deck boards you must either stay about 2 inches away from the edge of the board to make sure that you don't split the end of the board.

More on wood types and uses information

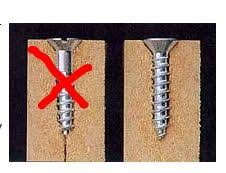

Also if you are using tapered head screws you might want to consider using a tapered drill bit to recess the hole along the tapered head of the screw to sink in flush to the surface of the wood because if you don't the taper part of the screw head might split the wood also if you force the screw had flushed to the surface.

Driving Screws into MDFI often use medium-density fiberboard (MDF) for my shop jigs and fixtures. There are many things I like about MDF. It's stable, heavy and costs about half as much as cabinet-grade plywood. One thing I don't like about MDF is its tendency to split along the edge of a workpiece. But, luckily, there are a couple of things you can do to avoid this problem. MDF tends to split most often when drilling and screwing in its edge, especially when using a tapered woodscrew, left above. It acts like a wedge to drive the workpiece apart. So I've gotten into the habit of using a straight-shanked screw, right above.However, a straight-shanked screw isn't a cure-all. Even when using a pilot hole and the right screw, MDF can still split out. So one final precaution is to support the sides by clamping an ordinary handscrew across the workpiece, see the photo at left. It makes it almost impossible to split the MDF.Try these two tips the next time you're working with MDF and you shouldn't have any problems with splitting.

Source: Driving Screws into MDF

Whether your installing baseboards or deck boards or putting up wood shelving Mississauga handyman carpentry can help.

REFERENCES HERE BELOW

YouTube: https://www.youtube.com/user/MississaugaHandyman

facebook: https://www.facebook.com/MississaugaHandyman

twitter: https://twitter.com/HandymaninSauga

google : https://plus.google.com/b/105990808681909578075/

yelp: https://www.yelp.com/biz/mississauga-handyman-mississauga

LinkedIn: http://www.linkedin.com/in/expertpainter

Mississauga Handyman

Address: Mississauga, ON L4T

Phone: (416) 568-3547

Email: mississaugahandymanservices@gmail.com

Website: https://www.mississaugahandyman.com/